Reflow soldering system with nitrogen atmosphere

The VisionXC with nitrogen atmosphere stands for maximum process reliability and reproducible soldering quality in modern electronics manufacturing. The targeted use of protective gas minimises oxidation at solder joints – for clean and durable connections. The system is designed for lead-free soldering processes and features a customised transport system that enables flexible production with different throughputs and batch sizes.

Stress-free cooling & transmission zone

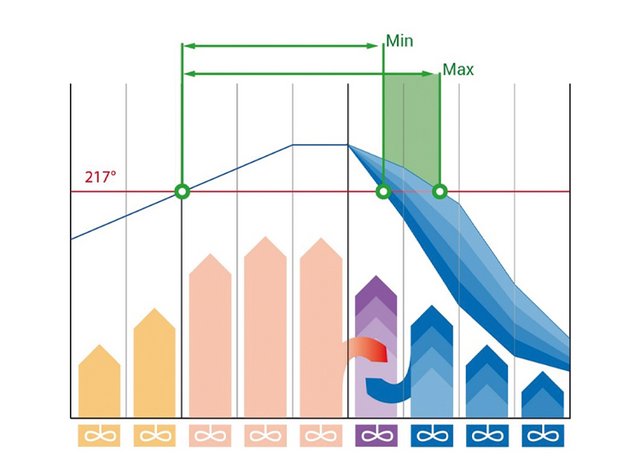

Depending on the type of system, the VisionXC has a multi-stage cooling section. Optional separately controllable fans in the individual zones allow you to adjust the cooling gradient to suit your requirements.

The system has a transmission zone, which is located in the transition between the peak and cooling areas. A heating module is installed in the first cooling zone, which can be switched on as required to cool large or sensitive assemblies particularly gently.

Precise temperature control

The powerful multi-zone heating system ensures uniform temperature distribution and fast heating times. Each zone can be controlled individually to maintain the optimum temperature profile precisely. Optimised air flow guarantees uniform heating of the assemblies, while the integrated cooling zone ensures controlled and gentle cooling – ideal for sensitive components and complex assemblies. It guarantees maximum process stability with minimal ∆T.

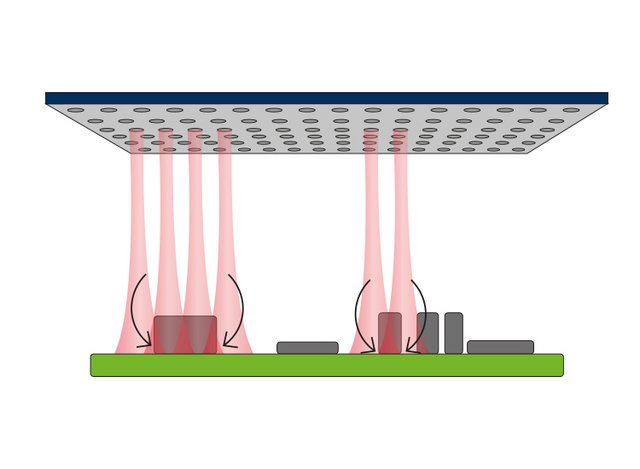

Intelligent flux management

The innovative MARS & FMS flux management system efficiently cleans the process gas atmosphere and keeps the plant clean, extending maintenance intervals and ensuring consistently stable process conditions.

In conjunction with the controlled nitrogen atmosphere, this creates a clean, controlled and efficient process environment – for maximum quality and plant availability.