Profiling and monitoring of the soldering process for highest quality requirements

ProMetrics was developed for monitoring thermal profiles during the soldering of electronic assemblies. It checks how well the created profile meets the required predefined specifications. An envelope graph visualizes deviations of the temperature profile from the specified temperatures. ProMetrics can be used for single and dual lane systems with and without vacuum.

Profiling with equipment from Solderstar

With Solderstar's many years of experience, we have a competent partner by our side for the creation and optimization of temperature profiles during reflow soldering. The Solderstar PRO thermoprofiling systems include a compact data logger with Solderstar Smartlink connectors. The system transmits live profile data directly to Solderstar's AutoSeeker software from Solderstar. After that, the profile can be transferred directly from the Solderstar interface to ViCON under ProMetrics.

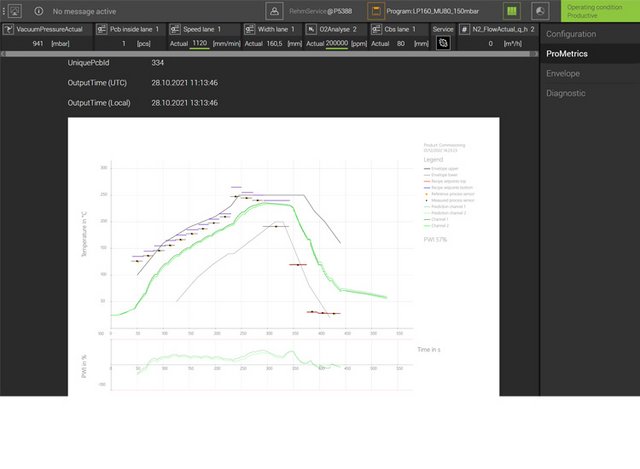

Graphic monitoring of the reflow process

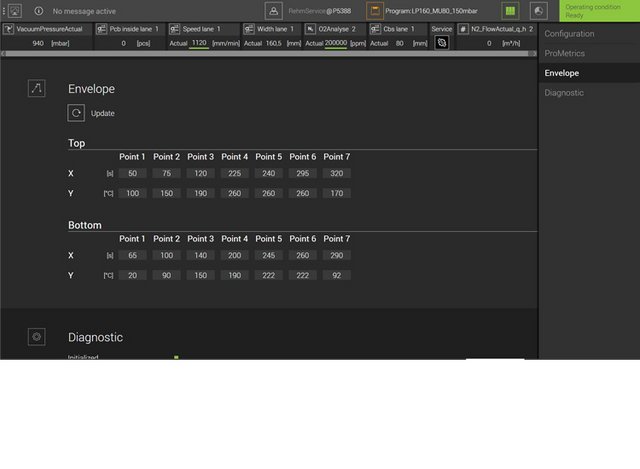

In the ViCON, the limits of the process can be defined by means of the envelope curve. The generation of real-time data per assembly allows the exact determination of the position of the assembly and reliably detects any deviations or delays in the soldering system. Approaches to the specification limit are detected immediately. In addition, the PWI (Process Window Index) is displayed.

ProMetrics in Practice

With ProMetrics, we offer you for the first time a tool with which you can stably determine whether the preset profile lies within the defined envelope curve in single, double-track and also vacuum systems. In addition, the integrated system in the ViCON offers data analysis per board and direct transfer of the data to the MES.

Highlights ProMetrics

- Process monitoring with live data

- Graphic evaluation of the results

- Independent probes

- Complete integration into the HMI

- For ALL Rehm Reflow Systems

(incl. Dual Lane and Vacuum) - No external interfaces